The need for masks is abundantly necessary during this present situation, and for those on the front line and working for essential business, the stress of not having the necessary items to help keep them safe has undoubtedly added to this already precarious time in our lives.

To help combat this issue is CoverAid PHL, which as its website states, is a coalition of representatives from hospitals, universities, manufacturers, government and small businesses collaborating on solutions for personal protective equipment.

This new task force was started by Mel Baiada (Board Member, BAYADA Home Health Care), Kendra Brill (DeSimone Group Investments, CHAR-COAL Apparel), John Venafro (local expert in Philadelphia manufacturing), Evan Malone (Founder of NextFab), Tony Sacksteder (WhiteSpace Labs, Project Development Consultant) and Elissa Bloom (Director of the Philadelphia Fashion Incubator), and together the six have joined forces to make this incredible effort to help save lives and keep people healthy.

“I was monitoring the news, and with NextFab being in the prototyping and product development services industry, we have contacts in manufacturing but also in area hospitals, so we knew about the need through those channels as well,” says Evan Malone. “I was starting to talk to organizations that Next Fab deals with about what they were hearing and what opportunities they were seeing to reduce the challenges [for providing masks]—that was really what planted the seed in my mind to start contributing directly to production.”

The story is similar for Elissa Bloom as well, who was called on by the Deputy Director of Commerce for the city to reach out to contacts and try and figure out a way to make these masks that are so desperately needed. With the virus spreading so rapidly, those behind CoverAid PHL had to figure out a way to be even quicker and more efficient with no real guidelines or long-term game-plan, just a will and a way.

“We all decided to come together and combine our expertise and resources and create a task force and create a platform so we aren’t double-dutying on similar work,” says Bloom. “We’ve been working fast and furious, and what started with designers through my network has turned into over 170 sewers.”

Banding together the different forces to make CoverAid PHL possible has taken hard work, creativity and an adaptable way of thinking. Something this impactful at this scale has not happened in our lifetime, and the efforts to help stop the spread of this virus needs to be just as poignant—but that has not come without it’s own set of problems.

“The proverbial fixing an airplane while you’re flying it—those types of analogies are very apt here,” says Malone. “A lot of grassroots efforts were underway—people were making masks, some were making respirators, or ventilators and all of these things were happening. I think what some of the immediate challenges we faced were a lack of connection to hospitals and other healthcare organizations to understand the need and what they could work with, or if any other projects would be interfering with each other’s effectiveness. We wanted to think about what the best designs and best approaches might be. What I think we each have been trying to do, is to put all of those efforts together and try and connect them with hospitals and other people who have expertise in what the need actually is and what would work. There is a much greater awareness to all of those different efforts going on and I think we are making progress on getting them aligned.”

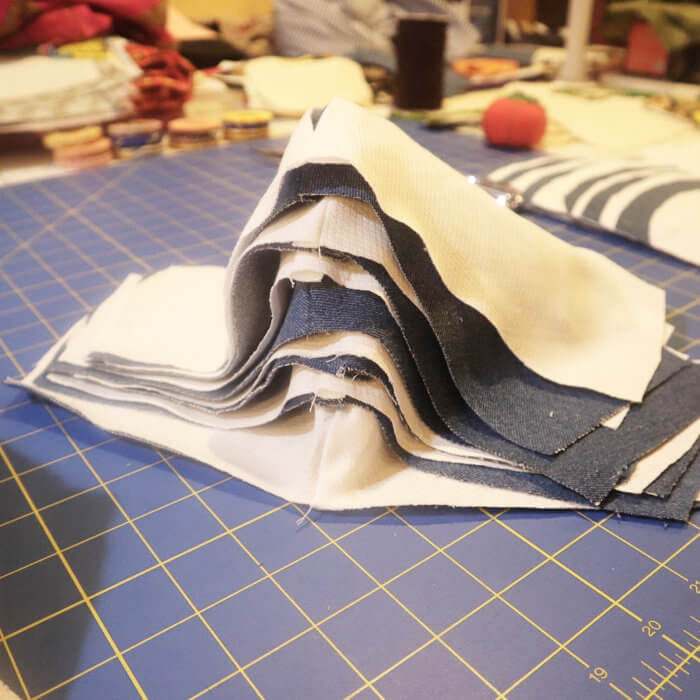

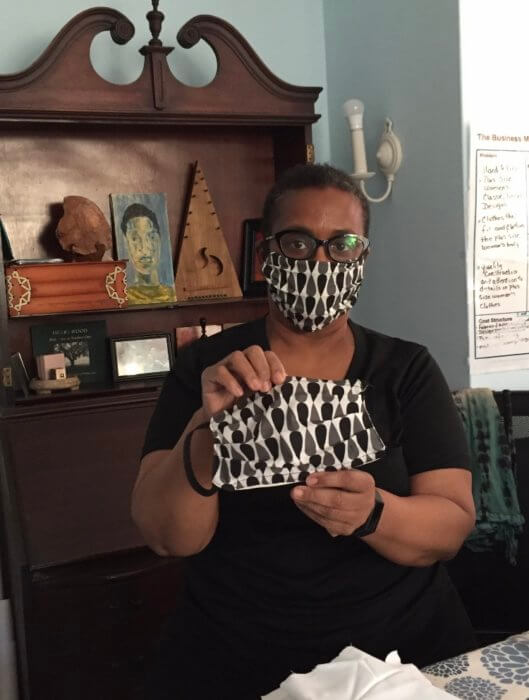

Working with John Venafro, CoverAid PHL was able to create a design and pattern that health care providers would be able to use, which they did produce and receive approval from those organizations. First and foremost, the task force will be supplying them with masks first until reprieve comes and then start supplying to other essential businesses such as the food-service industry. Already, there have been requests for thousands of masks from Temple University Health, Bancroft, Anderson Cancer Center, Cooper Hospital and Liberty Lutheran, with more certainly underway. The masks are sewed by volunteers who have dedicated their time and effort to this crucial cause.

“We have Anne Millman who is the head coordinator overseeing the sewers, and what we did was break them up into groups of 25 and have team leaders (many of who are Philadelphia Fashion incubator committee members including Latasha Hall, Julia Turner Lowe, Janell Wysock, Parris Little, Victoria Wright and Jovan O’Connor) who oversee their teams and field any questions, and are even working to get video up for the site on the mask-making process,” says Bloom. “We have a pick-up and delivery service too, we want to streamline and make it as easy and safe as possible for the sewers. We’re working with Sew Face Masks Philly, which also launched around the same time. We are very fortunate to be able to collaborate with them with the delivery service because they already have that in place and they have safety protocols in place for all of that as well.”

With Bloom leading the way on the DIY front, Malone, who works more on the production side, has also had to figure out a way to meet the needs of organizations while working through this unknown territory.

“In a home setting, you can prototype some of these solutions, but then when you want to make 10,000, that’s a very different challenge. How do you actually buy the materials? We had to put together in essence, multiple companies to do this and it’s all volunteer at this point. Different organizations coming together and sharing information that they normally would not do, but they’re willing to collaborate around this challenge. We’re trying to connect them, find sourcing opportunities and then find creative ways to handle the financial piece,” says Bloom. “In terms of buying materials, Bayada has been hugely valuable. They’ve been wanting to step up and provide deposit money, NextFab has been able to be a purchasing agent for getting materials flowing as well and that’s how we have started the process of going from volunteer-produced masks toward factory-produced masks. Those efforts are underway now.”

Just last week, 736 masks were made, and with the factory effort underway, there are 20,000 pieces cut in a cutting facility (Coates Brothers Cutting) and 10,000 which have also moved to sewing factories (T&T, Eric and Christopher, and Matthew Cole, Inc.). What CoverAid PHL is aiming for and expecting is to get up to 20,000 masks per week out of the factories.

“The first priority has been healthcare organizations in particular, and we’ve been trying to focus on that first and foremost. Once more masks come for healthcare workers from across the country or even overseas, we can shift the need to those who work in other essential business who need them,” adds Malone. “People in food service, food distribution, transportation and logistics who are still essential to keeping the economy running— those people don’t have much for supplies, and our next focus would be supplying those industries and those people.”

The labored efforts made by the team behind the task force just goes to show how resilient the City of Brotherly Love can be, our most notable mascot in recent years didn’t become Gritty for no reason. CoverAid PHL has made amazing progress, but they are also looking for help with more volunteers (there is a form and questionnaire to fill out on the official website if you’re interested in sewing) or donation of materials and funds (to go both towards the efforts and the volunteers who are working tirelessly.)

“I always think of Philadelphia as a maker city, and it’s just been incredible the people that want to help and get involved. It really is a group effort. We’ve been working hard to get these systems into place to make it as easy and seamless for sewers as we can,” says Bloom. “We’re evolving daily and learning as we go along. I think it just validates what the city is all about—all of us from different areas have really been able to band together for the greater good and make a difference here in the community.”

To learn more information or to get involved, visit coveraidphl.org